Nam Bee MasterMix Custom Compounding

Quality Raw Materials such as Standard Malaysian Rubber (SMR), Synthetic Rubber, High Tech Carbon Black and various Chemicals.

All the raw materials are fed into the internal mixers (banbury).

Using time, temperature, ampere & different mixing sequences, up to 13 different raw materials are evenly mixed to achieve uniformity, consistency & perfect dispersion & homogenity.

Using time, temperature, ampere & different mixing sequences, up to 13 different raw materials are evenly mixed to achieve uniformity, consistency & perfect dispersion & homogenity.

The dump temperature of the Mixed Rubber Compounds or Masterbatch are in the vicinity of 150 – 160°C.

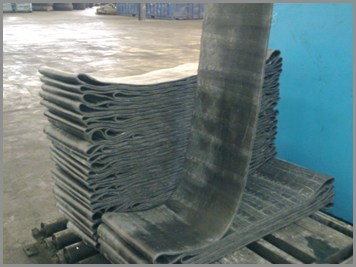

In order to prevent it from scorching or degrading, the Mixed Rubber Compounds or Masterbatch are quickly air cooled to room temperature through our High Air Velocity Festooner.

In order to prevent it from scorching or degrading, the Mixed Rubber Compounds or Masterbatch are quickly air cooled to room temperature through our High Air Velocity Festooner.

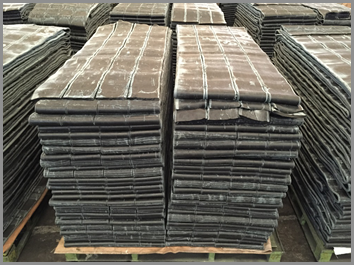

The result is perfectly mixed Rubber Compound or Masterbatch that will exhibit its full potential character and strength in its designed application.

These products are then further moulded into new tyres, retreads, conveyor belts, bridge bearing, dock fenders, engine mountings, wind screen wipers, o-rings & seals and other various products.

These products are then further moulded into new tyres, retreads, conveyor belts, bridge bearing, dock fenders, engine mountings, wind screen wipers, o-rings & seals and other various products.

Quality Control Laboratory

Our list of testing equipments includes:

1. Rheometer

2. Mooney Viscometer

3. Tensile Tester

4. Din Abrasion Resistance

5. Specific Gravity (Density)

6. Hardness Tester

7. Microscopic Tester

8. Lab Mill

9. Lab Press

Our list of testing equipments includes:

1. Rheometer

2. Mooney Viscometer

3. Tensile Tester

4. Din Abrasion Resistance

5. Specific Gravity (Density)

6. Hardness Tester

7. Microscopic Tester

8. Lab Mill

9. Lab Press